If you have been asked to transport goods, especially heavy goods, you must use the correct load restraints before starting your journey. Using load restraint equipment such as cam buckles and ratchet straps prevents your load from coming loose in transit. Failure to secure your load in the correct manner could result in damaged goods, as well as injuries and possibly fatalities if your unsecured load causes an accident.

If you are transporting your load across continents or simply just moving a loaded pallet by fork lift in a warehouse, regardless of the distance you intend on travelling, ratchet lashings must be used.

It is important to note that, just with any other equipment that is used to transport loads, ratchet straps have their own Working Load Limit (WLL) and their own Minimum Breaking Strength. The break strength is the amounts of weight a ratchet lashing can withstand without breaking. The breaking strength of each component of a ratchet lashing is independently test. But like everything, the ratchet lashing is only as strong as its weakest point, so the part of the ratchet lashing that is the weakest is considered to be the break strength of the entire lashing.

From the Minimum breaking point, the working load limit can be calculated by taking 1/3 off the break strength. So this means that the ratchet lashing with break strength of 300kg has a Working Load Limit of 1000kg.

Remember to check the working load limit of your ratchet lashing before use, to make sure they are able to withstand your load.

How to use ratchet lashings

When you receive your ratchet straps they will require some basic assembly. This can get quite confusing, so we have provided a simple 5 step guide to make sure you have assembled them correctly.

- Open the ratchet handle, and feed the webbing though the ratchet handle – from the bottom

- Feed the webbing over the top of your ratchet handle

- Fasten the hooks to the tie down points.

- Pull the webbing taught, removing any slack, to the tension you require.

- Pump ratchet until your load is secure

Remember to tie off any excess webbing, and to check that your load is completely restrained and secure before commencing your journey

How to maintain ratchet lashings

Over time, with excessive use or negligence, your ratchet straps will wear down, and eventually become unusable. However, if you look after you ratchet straps correctly, they can last a very long time.

To maintain good working order of your ratchet straps, we at SafetyLiftinGear recommend;

- Before you using any ratchet strap or cam buckle make sure they have been inspected. If there are any signs of damage, do not use.

- Keep your straps out of direct sunlight when in storage. Sunlight can cause polyester straps to become brittle and can lead to the straps losing their strength and breaking whilst in use.

- Store ratchet lashings in a dry place. If your lashings get wet, make sure you dry them off completely before storage to prevent mildew and mould.

Here, at SafetyLiftinGear we supply a large variety of Ratchet Lashings, specifically designed to help you transport a variety of loads, and attach to various tie down points. Below are some of our best selling Ratchet Lashings:

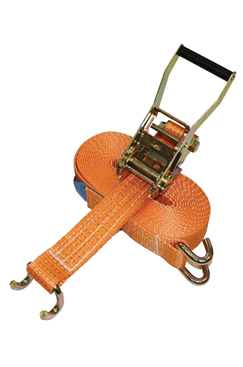

Ratchet Lashing with Open Rave Hooks

Rave hooks ratchet lashings are widely used for attaching loads to commercial vehicles or trailers because of their ease of application. This product is available in 3 lengths (6 mtr, 8 mtr and 10 mtr) and has a minimum breaking strength (MBS) of 5 tonnes.This ratchet lashing is trusted by many UK transport companies as it is strong, reliable, shock absorbent and extremely hard wearing.

More Information About this Product >

Ratchet Lashing with Chassis Hooks

Closed rave hooks (chassis hooks) are a face and effective way of restraining your load to your commercial vehicle, flatbed lorry or truck. Again, these types of ratchet straps are extremely popular with many UK transport companies because of their ease of application. Simply hook the ratchet lashing to your truck or lorry directly for secure transit.

Here at SafetyLiftinGear, we have a range of ratchet lashings with chassis hooks available, all with different working load limits and different lengths.

Full Range of Ratchet Lashings with Chassis Hooks >

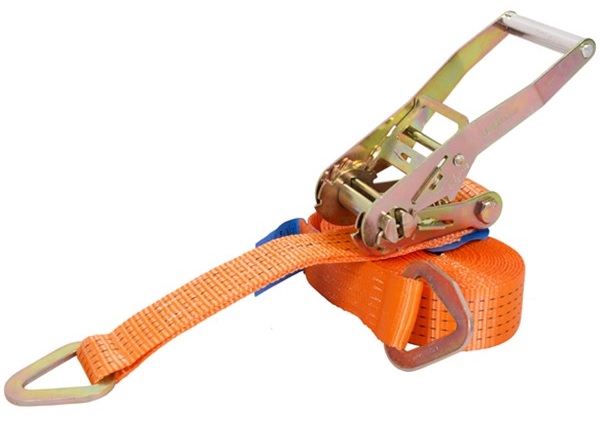

Endless Ratchet Lashing

The endless ratchet lashing is a lashing that has no hooks or fixing points. If you are required to secure a load to pallets, racking or you want to secure items together that do not need to be secured down, then an endless ratchet strap is the perfect choice.

These lashings are available in various lengths and Minimal Breaking strengths.

Browse Our Range >

Please ensure that you have selected the appropriate ratchet lashing for the intended job. If you have any questions regarding our range of lashings, then please contact us.